March 1, 2023

Helping construction material manufacturers reduce the energy consumption, carbon footprint of heating and cooling homes

Patent-pending, automatable process from Purdue engineers improves the viability of incorporating phase change materials into bricks, concrete panels and drywall

WEST LAFAYETTE, Ind. – Heating and cooling homes carries a hefty economic and environmental price tag. The U.S. Energy Information Administration reported more than half of all home energy in the United States is used for heating and cooling, and it also represents more than 14% of the nation’s overall energy use. According to the World Green Building Council, the buildings and construction sector is responsible for 39% of global energy-related carbon emissions.

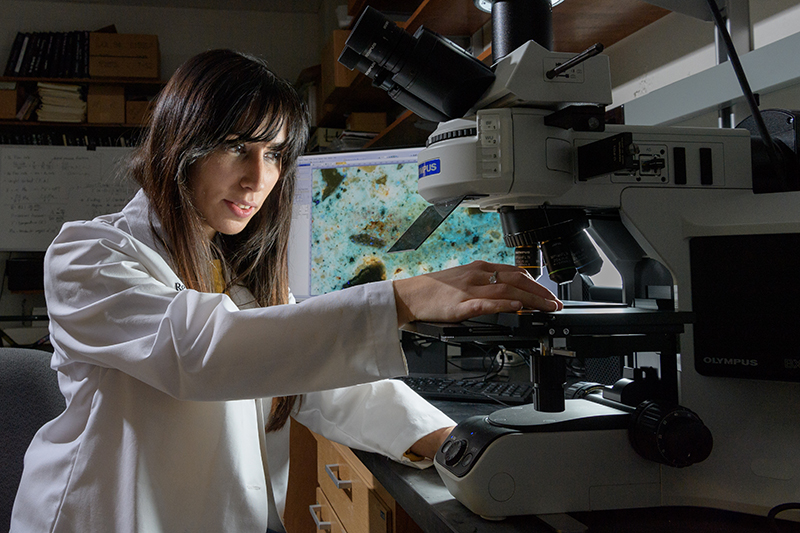

Mirian Velay-Lizancos, a Purdue University assistant professor of civil engineering from the Lyles School of Civil Engineering in the College of Engineering, is addressing these issues. She and researchers in her laboratory have developed a patent-pending, scalable, automatable process that improves upon the traditional method to incorporate phase change materials, or PCMs, into construction materials.

The incorporation of PCMs like paraffin, esters and salt hydrates into building envelope elements moderates the effect of outside temperature changes on the indoor environment. They convert changes in thermal energy into phase changes by transitioning from a solid into a liquid, or the opposite. They provide useful cooling or heat by absorbing or releasing energy during those transitions.

“Incorporating PCMs reduces energy consumption in buildings, which reduces carbon dioxide emissions and operational costs,” Velay-Lizancos said. “It also decreases water permeability of construction materials.”

PCMs are used in a building’s envelope, or the doors, exterior walls, foundations, roofs, windows and other components that create a barrier between the indoors and the outdoors. The thermal properties of building envelopes play a key role in a building’s energy consumption.

“Increasing the heat storage capabilities of building envelopes would reduce the effect of temperature fluctuations in a building,” Velay-Lizancos said. “This would increase the thermal comfort of the building and decrease energy consumption, carbon dioxide emissions and related economic costs of heating and cooling. It also would make buildings more resilient and energy independent and less susceptible to power outages and other energy supply issues.”

Velay-Lizancos said traditional methods to add PCMs in construction materials have drawbacks.

“Currently, PCMs are incorporated into other materials via microencapsulation or macroencapsulation,” Velay-Lizancos said. “However, these methods limit the use of PCMs. Microencapsulation has a negative effect on the strength and durability of construction materials. Macroencapsulation limits the shape and production method of construction materials.”

Velay-Lizancos’ method uses liquid immersion and a vacuum to incorporate PCMs after construction materials like bricks, drywall and concrete have already been formed. A two-minute video of the method is online.

“This increases the strength, enhances the durability and increases the thermal inertia of the construction materials,” Velay-Lizancos said. “This new method also distributes PCMs so they are concentrated in the surface layer of the construction materials. More of the PCMs are in contact with external surfaces of the building envelope, which makes the PCMs more effective.”

Velay-Lizancos’ method requires only a vacuum system, which she said is very accessible and easy for manufacturers to work with.

“Users will need to be familiarized with the process, but they will not need special training,” Velay-Lizancos said. “The process could be easily automatized and incorporated into the production chain of precast elements like bricks, concrete panels, drywall and pavers, among others.”

Velay-Lizancos and her research group tested the innovation at the Pankow Laboratory in the Lyles School of Civil Engineering. The initial tests were conducted with commercial bricks and 15 minutes of vacuum time.

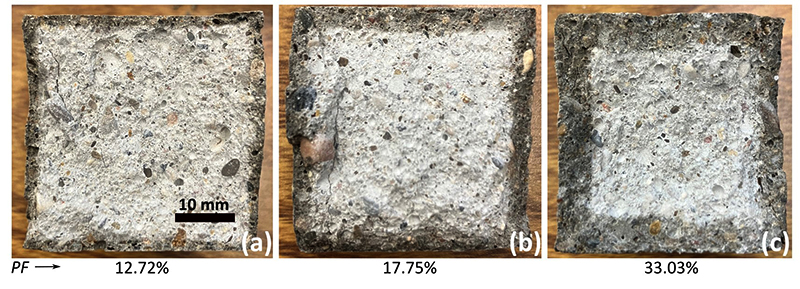

A large experimental campaign was conducted on cement mortars with three water-to-cement ratios and, therefore, different initial porosity levels. PCMs were incorporated into the mortars for three different vacuum periods: 15 minutes, 1 hour and 4 hours. Velay-Lizancos and her team observed an increase on the thermal inertia of 24% and over a 22% of increase in the compressive strength, with just 7% of the volume of the element filled with PCM.

Velay-Lizancos said the uneven distribution of the PCM concentrated in the surface layer makes the PCM more effective in enhancing thermal properties.

“The method used in this study introduces the PCM into the layer of the material that is closer to the material’s surface, meaning that more will be in contact with the external surfaces of the building envelope, resulting in more effective usage of the PCM,” Velay-Lizancos said. “Furthermore, this method pushes the PCM material into the capillary pores through the vacuum. Due to the capillary forces, leakage of PCM was not observed, even when the final composite was exposed to high temperatures well above the melting point of the PCM used.”

A paper about Velay-Lizancos’ research methods and results has been published in the March 2023 issue of the peer-reviewed journal Construction and Building Materials (Elsevier).

The next milestone to develop the PCM incorporation method is to build a full-scale prototype.

“This will allow us to visualize with cameras and sensors the thermal performance of the building envelope,” Velay-Lizancos said. “Clients will have the hard data and also be able to visualize the advantages of this technology.”

Velay-Lizancos disclosed the innovation to the Purdue Research Foundation Office of Technology Commercialization, which has applied for a patent on the intellectual property. Industry partners seeking to further develop this innovation should contact Parag Vasekar, psvasekar@pf.org, about reference number 2022-VELA-69766, “Novel Building Envelope Materials with Enhanced Durability That Reduce Energy Consumption.”

Velay-Lizancos and her team received support from the Lyles School of Civil Engineering and the Frederick N. Andrews Fellowship from The Graduate School at Purdue.

About Purdue University

Purdue University is a top public research institution developing practical solutions to today’s toughest challenges. Ranked in each of the last five years as one of the 10 Most Innovative universities in the United States by U.S. News & World Report, Purdue delivers world-changing research and out-of-this-world discovery. Committed to hands-on and online, real-world learning, Purdue offers a transformative education to all. Committed to affordability and accessibility, Purdue has frozen tuition and most fees at 2012-13 levels, enabling more students than ever to graduate debt-free. See how Purdue never stops in the persistent pursuit of the next giant leap at https://stories.purdue.edu.

About Purdue Research Foundation Office of Technology Commercialization

The Purdue Research Foundation Office of Technology Commercialization operates one of the most comprehensive technology transfer programs among leading research universities in the U.S. Services provided by this office support the economic development initiatives of Purdue University and benefit the university’s academic activities through commercializing, licensing and protecting Purdue intellectual property. In fiscal year 2021, the office reported 159 deals finalized with 236 technologies signed, 394 disclosures received and 187 issued U.S. patents. The office is managed by the Purdue Research Foundation, which received the 2019 Innovation and Economic Prosperity Universities Award for Place from the Association of Public and Land-grant Universities. In 2020, IPWatchdog Institute ranked Purdue third nationally in startup creation and in the top 20 for patents. The Purdue Research Foundation is a private, nonprofit foundation created to advance the mission of Purdue University. Contact otcip@prf.org for more information.

Writer/Media contact: Steve Martin, sgmartin@prf.orgSource: Mirian Velay-Lizancos, mvelayli@purdue.edu